POWERBIND™

High performance stitching wire

a powerful result of our intensive research and development.

Combining the needs of our customer and requirements of modern stitching machines, we developed a high performance stitching wire with superior properties that offers substantial quality and cost advantages in your wire stitching processes:

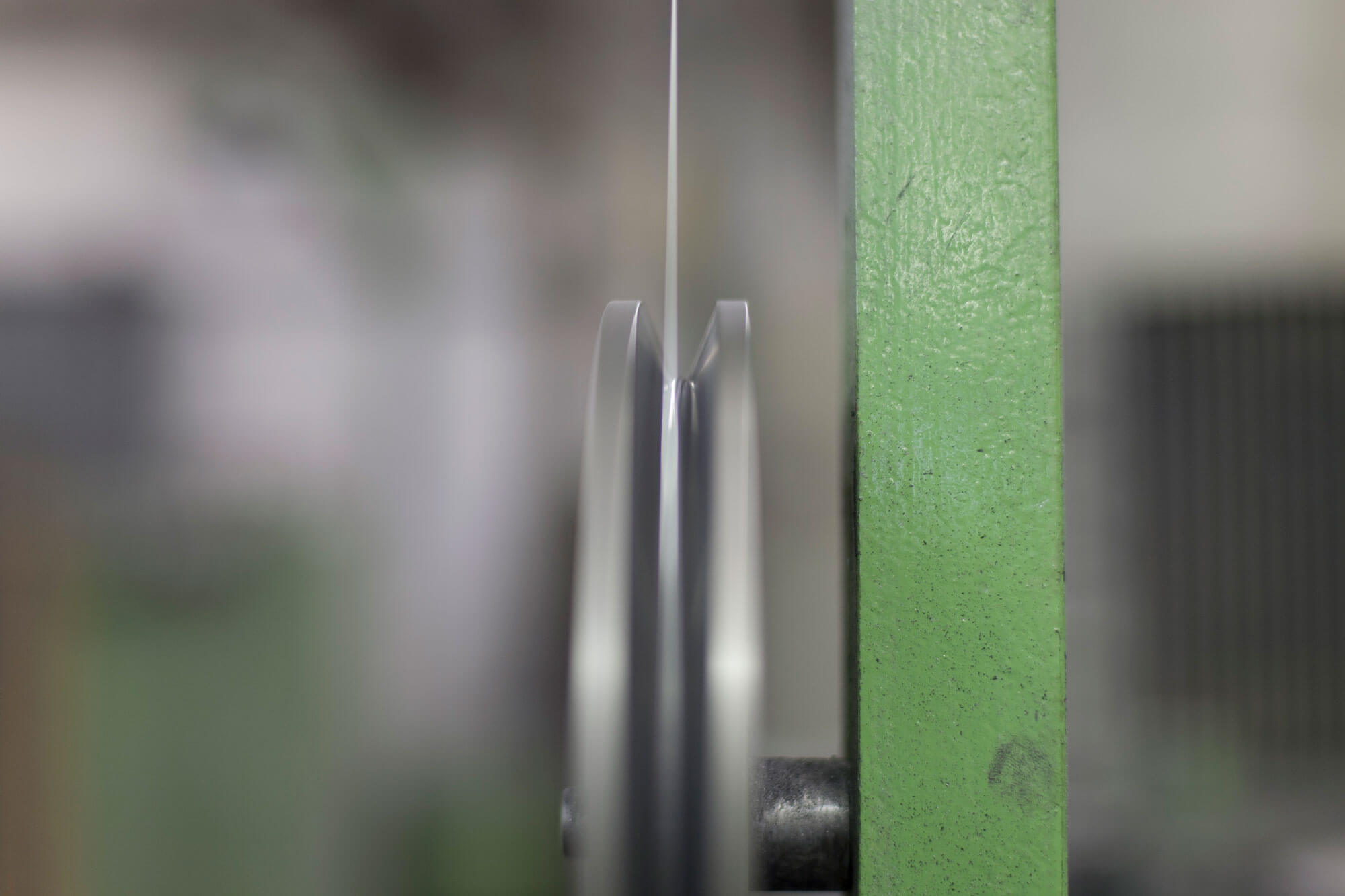

Accurate staple forming

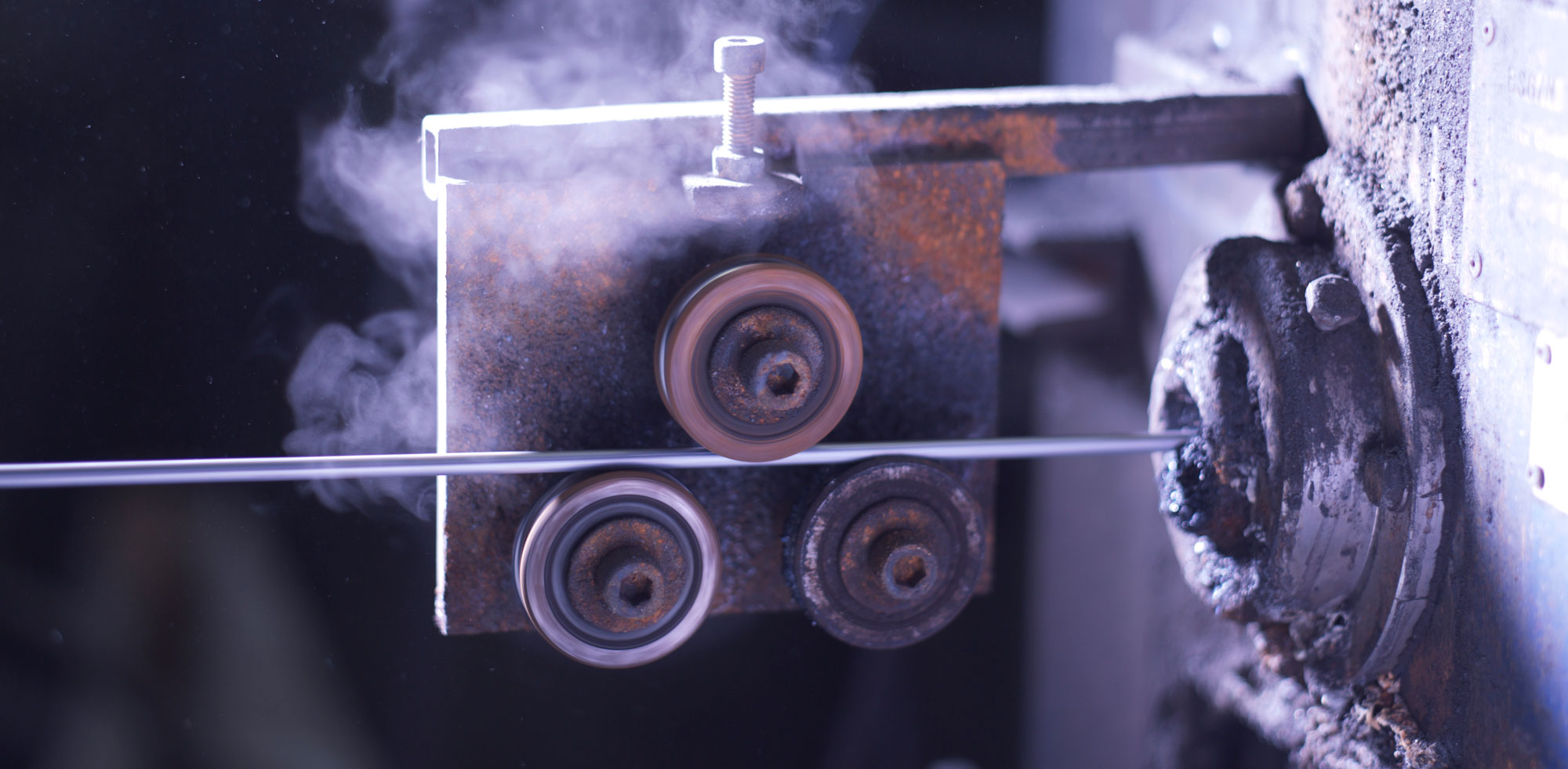

POWERBIND™ has superior workability, forming stability and perfect cutting characteristics which facilitates accurate staple forming. Therefore POWERBIND™ offers the highest product quality and improved bindery performance.

Solution to difficulties of stitching thicker products

POWERBIND™ has added strength that allows for a more flexible use of the same wire dimension across the broadest range of products. The need to change wire diameters for thickness variables is reduced or possibly even eliminated.

Trials show that POWERBIND™ can replace high carbon steel wire while providing superior quality and performance with less wear of parts.

Minimizing stacking height

Using lower gauge sized POWERBIND™ especially in small page count products reduces stacking height and minimizes logistical and handling issues.

Cost reduction

√ optimized set-up cost and reduced downtime due to more flexible use of the same wire dimension

√ lower storage cost due to reduced amount of different diameters used

√ replaces high carbon steel wire

√ reduction of material cost: since a smaller wire diameter can be used with our high quality wire, our customers can take advantage of having more stitches per kilogram or pound

POWERBIND™ is available in all standard dimensions and on all common coil types.