Brush wire/ Brush stapling wire

DDD offers brush wire for

Airport sweepers, street sweepers, and industrial sweepers.

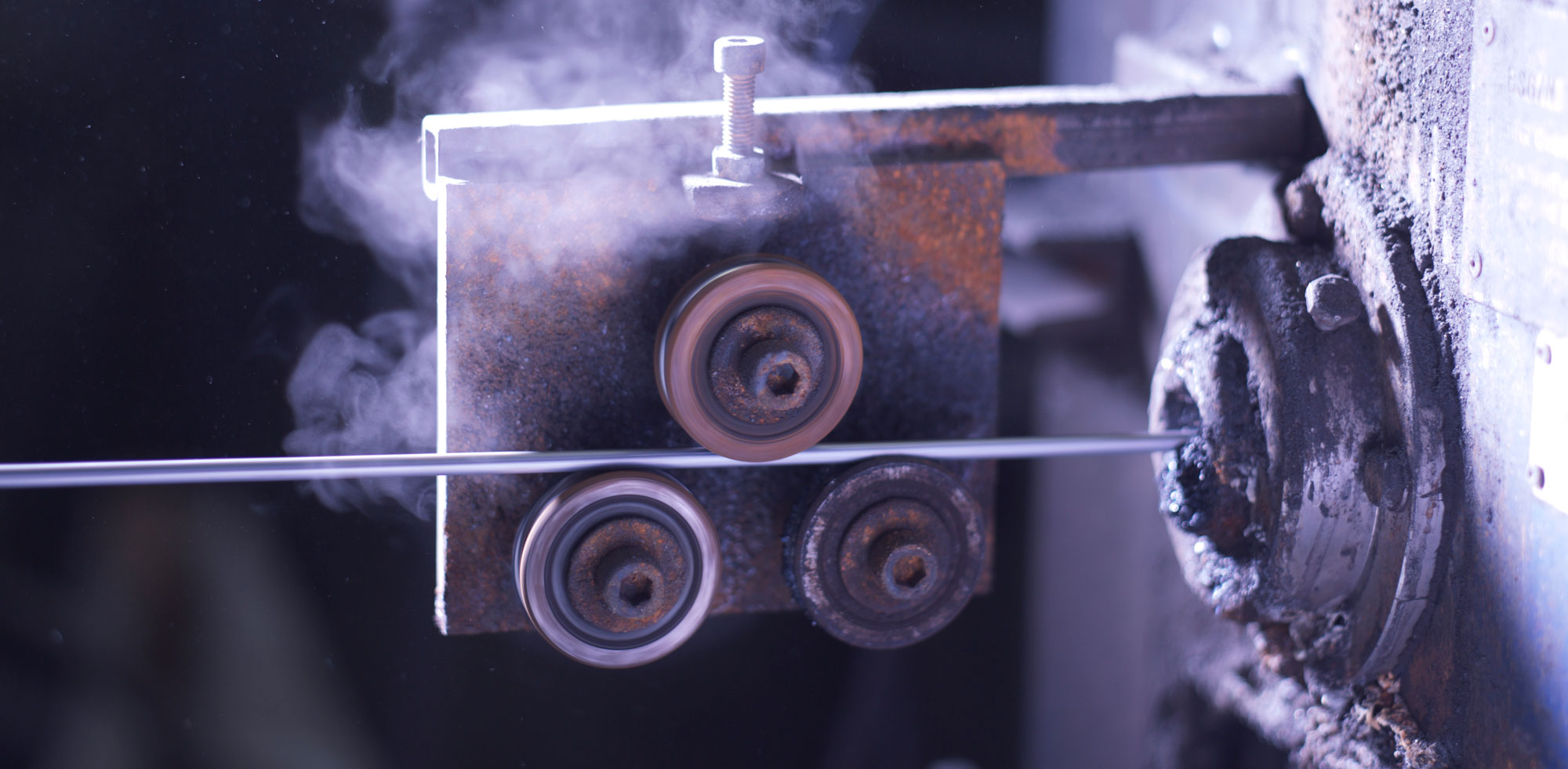

Nowadays, we can hardly do without modern sweeping machines with different brush systems. These brushes require sturdy, high-quality metal wires. A high wire content in the brushes increases their abrasiveness and thus, the sweeping performance.

Our drawn wire for the brush industry is characterized by uniform strength for trouble-free further processing.

Whether cassette brushes, disc brushes, sweeping rollers, or brush rings – every brush is only as good as its wire. With high-quality DDD wire, brush systems withstand the extreme pressures of removing snow, ice, and dirt.

Areas of application:

- Disc brushes – for all front-mounted and self-picking sweepers.

- Sweeping rollers – for all common front-mounted sweepers and self-picking sweepers.

- Weed brooms – for all sweepers and weed removal equipment.

- Cassette brushes and cassette brooms – e.g. for taxiway cleaning.

- Brush rings – for compact sweeping/cleaning machines.

Features:

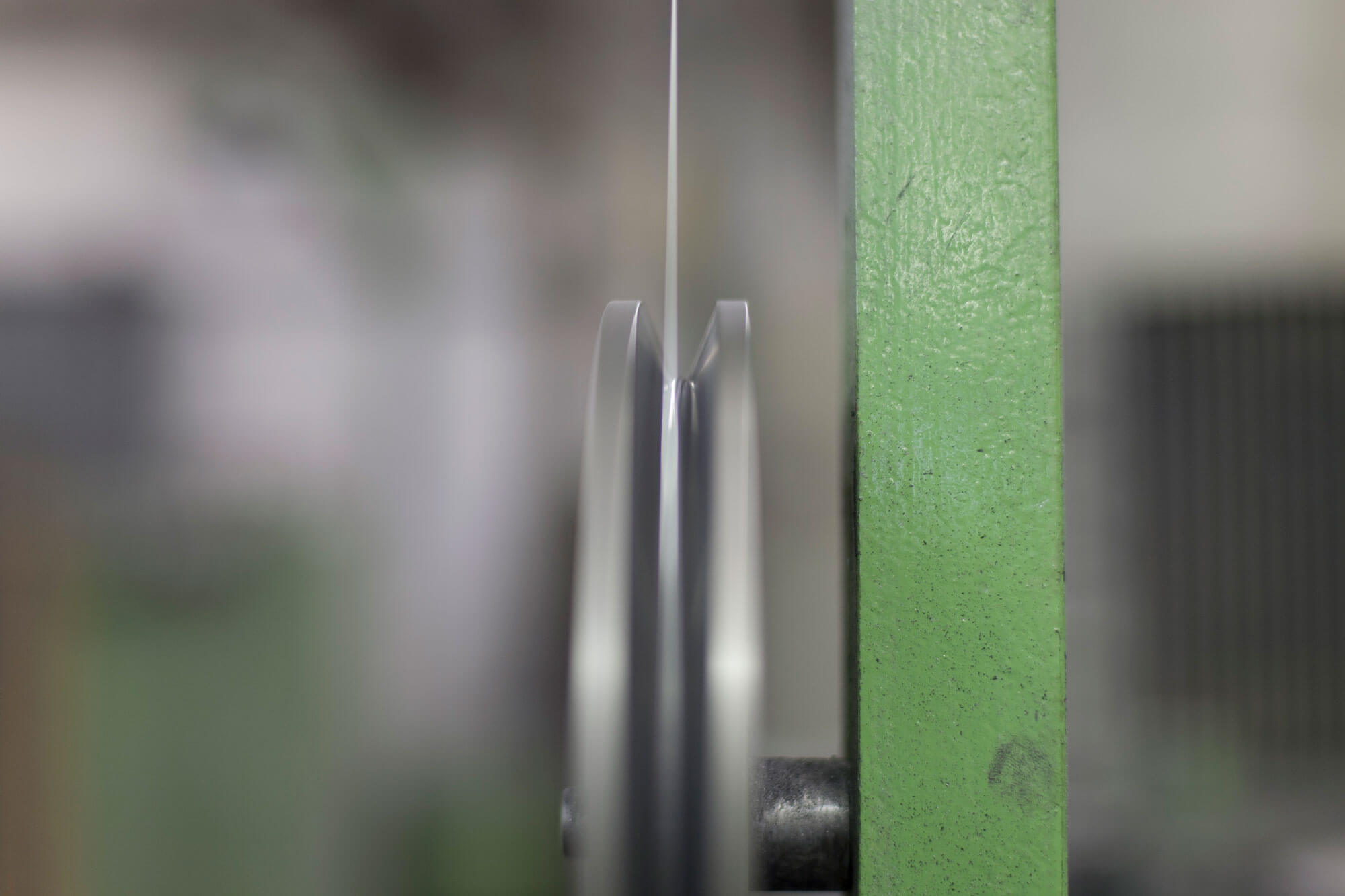

» High-carbon wires (C30D to C80D)

» Dimensional range 0.40 mm to 2.0 mm

» Strengths 600 to 2,500 N/mm²

» On spools with filling weights from 2 to 1,500 kg.

DDD also offers brush stapling wires

for the fixation of the bristles during brush production.

Features:

» Low carbon steel wires (C4D to C9D)

» Dimensional range 0.30 mm to 1.80 mm

» Strengths 400 to 1,100 N/mm²

» On spools with filling weights from 2 to 1,500 kg

» Also partially available as Easydrum variant (drum).