You are here: Home1 / Meshes and Engineered Products2 / Products3 / Sintered wire cloth laminate4 / Sintered fiber media

Sintered fiber media

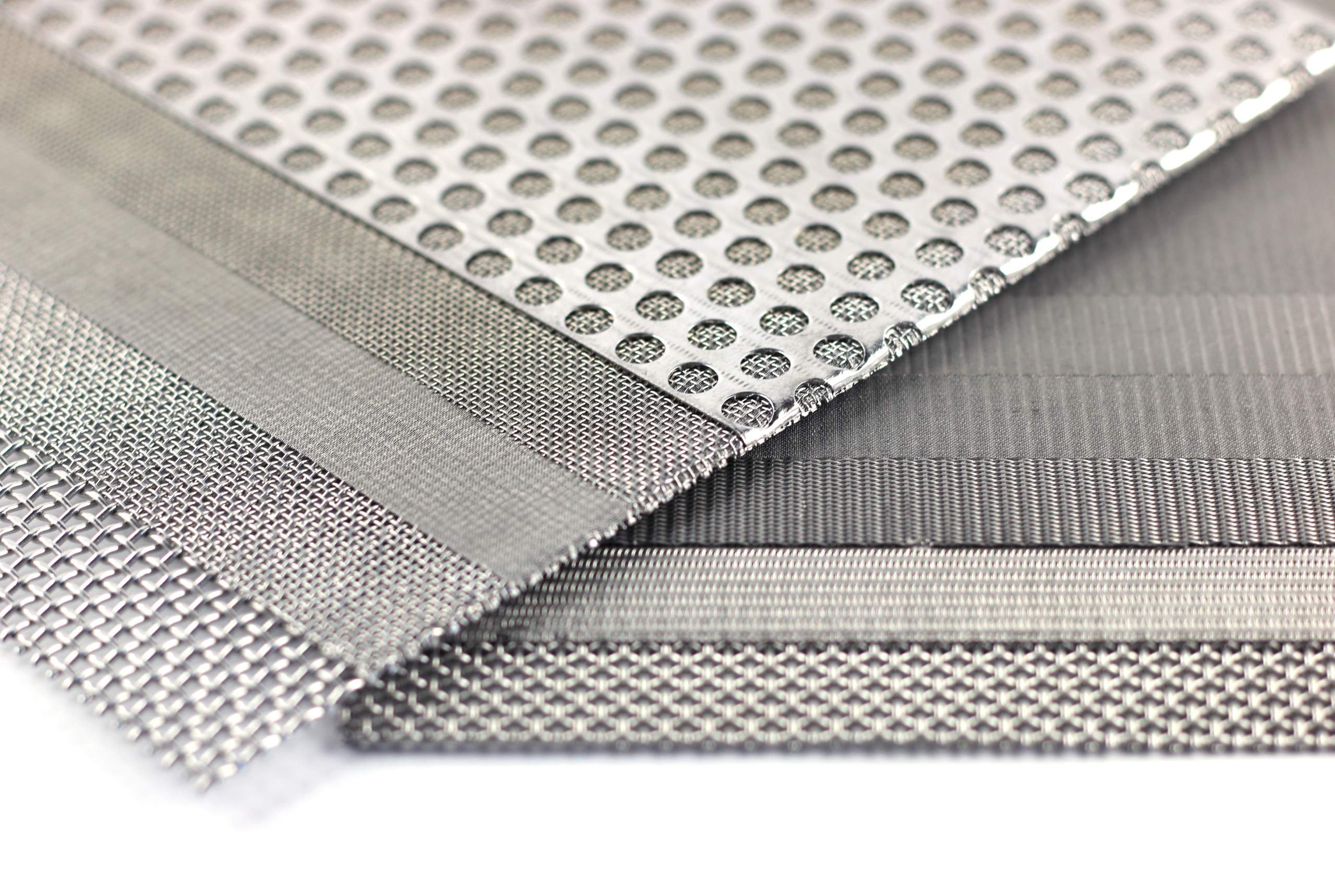

Metal fiber fleeces are laid, sintered, and calendered from different fiber layers with stainless steel fibers from 2 μm diameter. The result is a filter media that is easy to process and made of corrosion-& heat-resistant, and stable stainless steel material with precise filtration performance. We can design metal fiber fleece so that filter fineness, porosity, dirt-holding capacity, and stability meet the requirements.

Sintered fiber media is widely used in burner applications, but many other industries also take advantage of its excellent filtration performance.

Excellent filtration characteristics

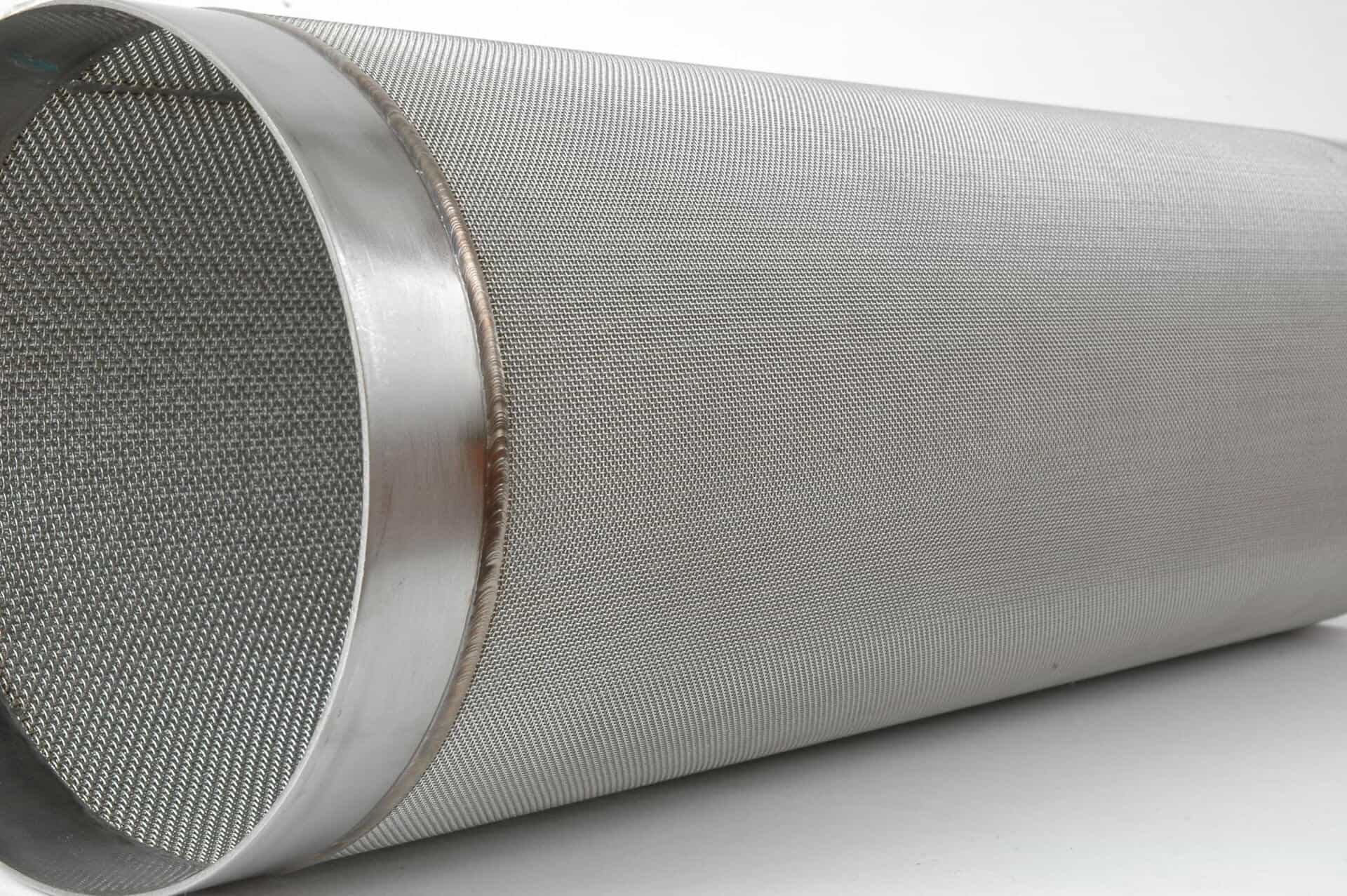

Our sintered fiber media achieves superior filtration efficiency by combining exceptional dirt-holding capacity with excellent flow properties. The precise selection of fiber diameters and basis weight are the key factors the success.

The structure of the stainless steel fiber felt is designed to control the pore diameter throughout the thickness. The result is a graded pore matrix. This allows our nonwoven fiber to trap the larger particles in the outer layers, while smaller particles can penetrate deeper into the matrix.

As a result, our sintered fiber media achieve a higher dirt-holding capacity and a longer service life in operation. Our metal fiber media can also be configured as a surface filter to trap particles on the outer layer when you want backflush applications.

Standard

| Name | Filtration rating μm | Bubble Point Pressure Pa (+/- 8%) | Air permeability L/min/dm^2 min | Dirt absorption mg/cm² (+/- 20%) | Thickness mm (+/- 0,05) | Weight g/m² | Porosity % (+/- 5%) |

|---|---|---|---|---|---|---|---|

| S3D | 3 | 12300 | 10 | / | / | / | 68 |

| S5D | 5 | 6000 | 35 | 2 | 0,43 | 1200 | 75 |

| S10D | 10 | 3700 | 100 | 4 | 0,62 | 1200 | 77 |

| S15D | 15 | 2600 | 130 | 6 | 0,42 | 750 | 78 |

| S20D | 20 | 1890 | 230 | 10 | 0,56 | 1050 | 75 |

| S25D | 30 | 1300 | 450 | 15 | 0,50 | 750 | 80 |

| S30D | 30 | 1300 | 450 | 15 | 0,50 | 750 | 80 |

| S40D | 40 | 975 | 580 | 20 | 0,72 | 1200 | 78 |

| S60D | 60 | 690 | 1100 | 30 | 0,60 | 750 | 85 |

| S100D | 100 | 630 | 1220 | 50 | 0,72 | 875 | 88 |

Medium

| Name | Filtration rating μm | Bubble Point Pressure Pa (+/- 8%) | Air permeability L/min/dm^2 min | Dirt absorption mg/cm² (+/- 20%) | Thickness mm (+/- 0,05) | Weight g/m² | Porosity % (+/- 5%) |

|---|---|---|---|---|---|---|---|

| M15D | 15 | 2600 | 150 | 10 | 0,70 | 1000 | 82 |

| M20D | 20 | 1890 | 300 | 15 | 0,67 | 900 | 84 |

| M25D | 25 | 1540 | 400 | 15 | 0,45 | 900 | 75 |

| M40D | 40 | 1020 | 550 | 25 | 0,47 | 900 | 75 |

Strong

| Name | Filtration rating μm | Bubble Point Pressure Pa (+/- 8%) | Air permeability L/min/dm^2 min | Dirt absorption mg/cm² (+/- 20%) | Thickness mm (+/- 0,05) | Weight g/m² | Porosity % (+/- 5%) |

|---|---|---|---|---|---|---|---|

| R5D | 5 | 6000 | 35 | 2 | 0,43 | 1200 | 62 |

| R10D | 10 | 3700 | 70 | 4 | 0,62 | 1200 | 70 |

| R15D | 15 | 2600 | 110 | 6 | 0,52 | 900 | 74 |

| R20D | 20 | 1890 | 230 | 8 | 0,46 | 900 | 74 |

| R25D | 25 | 1560 | 300 | 10 | 0,52 | 900 | 76 |

| R30D | 30 | 1300 | 500 | 20 | 0,56 | 900 | 80 |

Light

| Name | Filtration rating μm | Bubble Point Pressure Pa (+/- 8%) | Air permeability L/min/dm^2 min | Dirt absorption mg/cm² (+/- 20%) | Thickness mm (+/- 0,05) | Weight g/m² | Porosity % (+/- 5%) |

|---|---|---|---|---|---|---|---|

| L15D | 15 | 2400 | 200 | 7 | 0,27 | 600 | 75 |

| L20D | 20 | 1800 | 250 | 5,5 | 0,23 | 550 | 70 |

Delivery Options

Dorstener Drahtwerke supplies the desired metal fiber fleece as a single layer or also sintered with supporting layers of wire mesh for additional strength and flexibility – according to your requirements.

We offer nonwovens in various materials: 1.4301/6, 1.4401/4, nickel, Hastelloy and FeCrAl. Our maximum available sheet size is 1,500 x 1,200 mm.

Other specifications and media with mesh reinforcement are available on request.

The test specifications are for reference only. The air permeability at 200 Pa according to ISO 4022, the filtration fineness using the bubble point method according to ISO 4003 and the dirt pick-up according to ISO 4572 were tested.

Applications

Dorstener Drahtwerke is ISO 9001 certified and all our products are manufactured to the highest quality standards. Our staff is available to help you determine the right product for your application that meets your requirements and budget. Contact us today for more information!